Sontech International AB provides advanced soundproofing solutions for generators using patented Acustimet® and

VIBRALON 25 SB technologies to reduce noise and vibrations effectively.

About Sontech International AB

With over 30 years of expertise, Sontech International AB is a global leader in acoustic solutions. Our advanced soundproofing technologies, including Acustimet® and VIBRALON 25 SB, are designed to mitigate generator noise, addressing both airborne and structure-borne sound to ensure quieter operations in industrial, residential, and commercial settings.

From design to manufacturing, we provide tailored solutions for generator manufacturers and end-users, delivering high-quality, sustainable products that meet stringent noise regulations.

Our Soundproofing Solutions for Generators

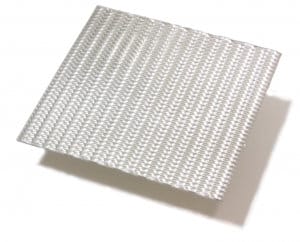

Acustimet®

Acustimet® employs microperforated panels to absorb airborne noise from generators, reducing sound emissions in enclosures and exhaust systems. Its lightweight, durable design is perfect for compact applications.

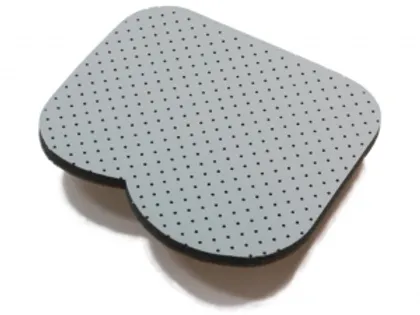

VIBRALON 25 SB

VIBRALON 25 SB is a viscoelastic material that dampens structure-borne vibrations in generator frames and bases, minimizing noise transmission and enhancing operational stability with sustainable properties.

How Soundproofing Generators works

Generators produce significant noise through mechanical vibrations and combustion processes, impacting both operators and nearby environments. Noise from generators is a combination of airborne sound, caused by engine exhaust and cooling fans, and structure-borne sound, transmitted through the generator’s frame and mounting. Typical sound pressure levels (SPL) for industrial generators range from 80–100 dB(A) at 1 meter, exceeding safe exposure limits set by OSHA (85 dB(A) for 8 hours) and causing disturbances in residential or commercial settings.

Airborne noise, dominant in the 500–4000 Hz range, results from rapid pressure changes in the engine and exhaust systems. Structure-borne noise, often in the 20–200 Hz range, arises from vibrations in the generator’s rotating components, such as pistons and crankshafts, which resonate with the frame. These low-frequency vibrations are challenging to mitigate due to their long wavelengths, requiring specialized damping materials.

Soundproofing solutions work by absorbing, damping, or isolating these noise sources. Sontech’s Acustimet® uses microperforated panels with a high absorption coefficient (α > 0.9) to capture airborne noise, leveraging Helmholtz resonance to dissipate sound energy as heat. This is particularly effective in generator enclosures, where space constraints demand lightweight materials. Acustimet® reduces SPL by up to 10 dB in the mid-to-high frequency range, creating quieter environments.

For structure-borne noise, VIBRALON 25 SB’s viscoelastic properties achieve a loss factor (η > 0.2), converting vibrational energy into heat. Applied to generator bases or frames, it minimizes resonance, reducing low-frequency noise transmission by up to 15 dB. Its durability against oil and temperature changes ensures long-term performance in harsh conditions, while its eco-friendly composition aligns with sustainability standards like ISO 14001.

Effective soundproofing also involves enclosure design and isolation. Sontech’s solutions integrate with sealed enclosures and vibration isolators, achieving total noise reductions of 20–30 dB in real-world applications, such as backup generators for hospitals or data centers. By addressing both noise types, our technologies ensure compliance with regulations like EU Directive 2000/14/EC and enhance user comfort.

Applications for Soundproofing Generators

Sontech’s soundproofing solutions are designed for various generator applications, including:

- Industrial Generators: Reducing noise in factories and construction sites to protect workers and meet regulations.

- Residential Generators: Minimizing disturbances in homes and neighborhoods for quieter backup power.

- Commercial Generators: Ensuring low noise levels in hospitals, data centers, and offices for operational efficiency.

Our solutions deliver compliance and comfort across diverse settings.

Why Choose Sontech for Soundproofing Generators?

Patented Technologies

Acustimet® and VIBRALON 25 SB provide superior noise and vibration control for generators.

Custom Solutions

We design tailored soundproofing systems for specific generator models and environments.

Sustainability

Our eco-friendly materials support sustainable noise control solutions.

Frequently Asked Questions

Why is soundproofing generators important?

Soundproofing reduces noise pollution, protects workers, and ensures compliance with noise regulations in residential and commercial areas.

How does Acustimet® help with generator noise?

Acustimet® absorbs airborne noise with microperforated panels, lowering sound emissions from generator enclosures and exhausts.

What role does VIBRALON 25 SB play in soundproofing?

VIBRALON 25 SB dampens structure-borne vibrations, reducing low-frequency noise transmitted through generator frames.

Contact Us for Soundproofing Solutions & Samples

Transform your generators with Sontech’s advanced soundproofing solutions. Contact us today for expert consultation.

Or reach us at: info@sontech.se | +46 8 445 60 60